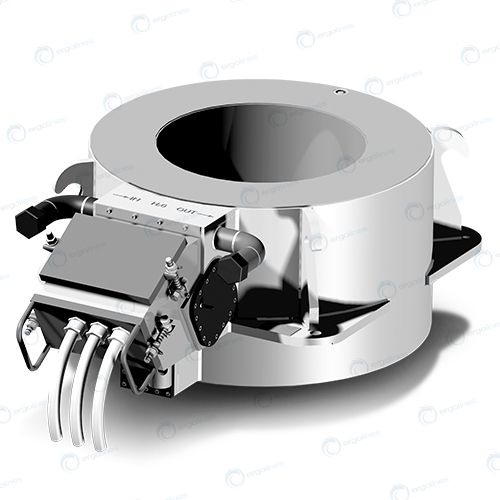

The electromagnetic stirrers are used in the continuous casting process to improve the product quality and to increase the steel production. According to the position along the casting strand and metallurgical effects, stirrers can be classified as mould, strand, and final stirrers. The benefits obtained using one or more EMS in combination include surface and sub-surface quality, internal and central soundness as segregation, porosity, and central cracks.

Electromagnetic braking of the hot metal flow in the mould of a continuous casting machine improves the quality of the cast steel by reducing the penetration of non-metallic inclusions. These are especially likely to occur during high-speed casting.

The benefits include surface and sub-surface quality, internal and central soundness as segregation, porosity, and central cracks.