We supply EHSd, EPSd or EPSr. We focus on the customer requirements even for the smallest installation. We supply different spray pressures and temperatures that can be optimally adapted in our multi-chamber system.

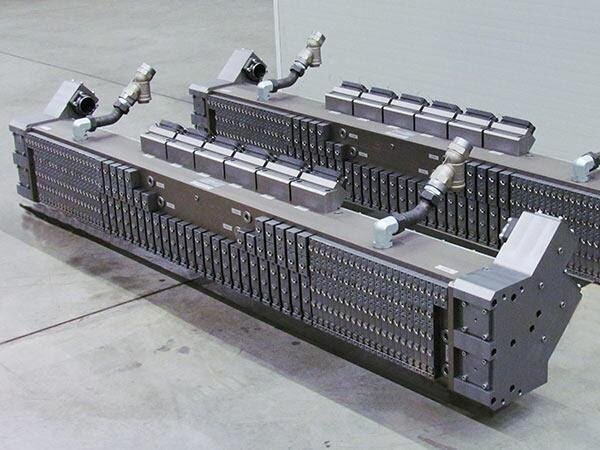

Modular Design

-

Maintenance–

Free Control due to implemented worst case filter in the pilot circuit -

Worst case–

Pipe- Filter(Optional) protection for the spray system -

Spray Bar Body-

Optimally matched to each requirement, we choose out of the following portfolio:

Solid material, welded profile, profile (semi-finished), Steel/Stainless steel/Aluminium -

Connector-

Fail-safe & distinctive fastened, 100% dense -

Medium Supply–

Medium connection according to customer’s requirements: Standard flange(SAE, FA, DIN-ISO, ANSI,etc)

Threads, hole pattern, welded special solutions -

Features & options-

Liquid sensor, Magnetic separator, Cable break monitoring, Pressure measurement, Temperature measurement, Automatic drainage

SPRAY PATTERN

PITCHPitch of >25 mm at 1:1 control and variable number of rows possible

NOZZLE COVERThe mechanically manufactured nozzle cover guarantees the optimal and tolerance-free positioning of the i-Jet nozzle to the roll.

I-JET FLAT SPRAY NOZZLEOur patented i-Jet nozzle delivers a stable and reproductive spray pattern, which is the basic for an optimal strip flatness.

We ensure, “BEST FLATNESS NON-STOP"