Hot Strip Mill & CSP Mill

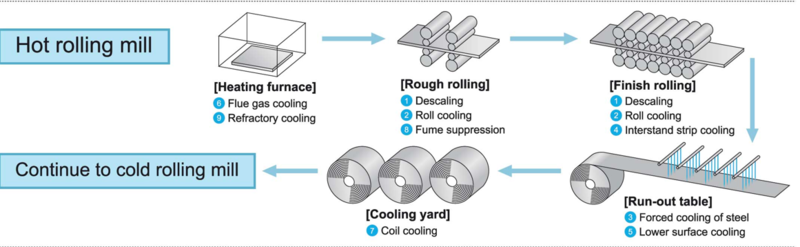

Hot strip mills in these days are either conventional hot strip mills or strip mills for rolling thin slabs. The primary function of the conventional hot strip mill (HSM) is to reheat the semi-finished steel slabs (rolled or continuously cast) to the rolling temperatures and then to roll them thinner and longer through a series of rolling mill stands driven by large motors and finally coiling up the lengthened steel sheet for its easy handling and transport. Coils are produced with an inside diameter of 750 mm on the coilers, with an outside diameter of up to 2400 mm and with the limitations of coil weight up to 220 kg per cm width. The hot strip mill supplies coils for cold rolling mill, strip shearing and slitting units as well as a finished product for shipment directly to the customers. Most material is transported out of the mill area by an automated coil handling system to the storage aisle.

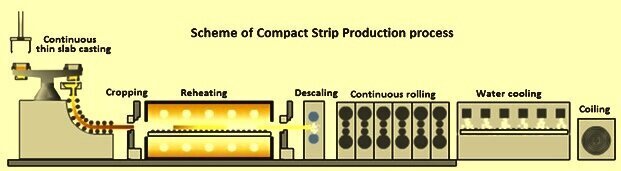

Compact Strip Production (CSP) is a novel technology developed in 1980s for casting-hot-rolling of thin slabs.This technology provides a more compact line and a more simple procedure as compared with the traditional hot rolling technology.

CSP produces high-quality hot strip in a single manufacturing line that combines casting, heating, and rolling. The slabs go into the CSP furnace for temperature equalization. Straight after that, the CSP mill rolls them to final strip thickness.

If you want to grow with the market, CSP is the perfect solution for you. Starting with a single-strand CSP plant, you can cost-effectively produce around 1.5 million tons hot strip per year. Later, simply add a second casting strand to double your capacity to more than 3 million tons per year.

- Skid button and Riders for Reheating furnaces

- Complete descaling system and Valves

- HAGC cylinder, Screw down nuts

- Auxiliary rolls for coil box

- Crop shear units

- Crop shear knives and holders

- Gear boxes, Gear Spindles, Gear Coupling, Universal Shafts for Finishing mills and roughing mills

- Chocks, Liner/ Wear Plates

- Cast Work Rolls

- Forged Backup Rolls

- Bearings

- Exit Table rolls or ROT rolls

- Down coiler pinch rolls

- Complete down coiler mandrel and system

- Coil Transfer Cars

- Barrel Coupling for cranes

- Roll Grinding Wheels

- Magnets for Lifting Coils

- Mechatronic Packages