Mechatronic Packages & Industrial Solutions

Combining product engineering and manufacturing in one single place offers the unique benefit of supplying in-house designed, manufactured and tested products.

For the metals industry, our Strip Processing Lines and Cold Mills stand for high-performance and cost-efficient solutions to meet the state of the art carbon and stainless-steel markets requirements.

We are offering solutions to other heavy industries such as tyre industry, forging or shipbuilding.

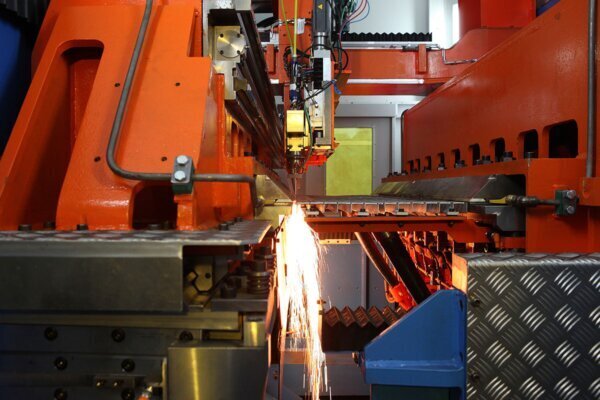

LASER WELDER HEAVY

From 0.7 to 7.0 mm

- LC, HSS, stainless, Si steel, without grade limitation

- Low operating cost thanks to laser cutting & welding

- Improved line flexibility with less transition limitation

LASER WELDER MEDIUM

From 0.25 to 4.0 mm

- LC, HSS, stainless, Si steel, without grade limitation

- Low operating cost thanks to laser cutting & welding

- Improved line flexibility with less transition limitation

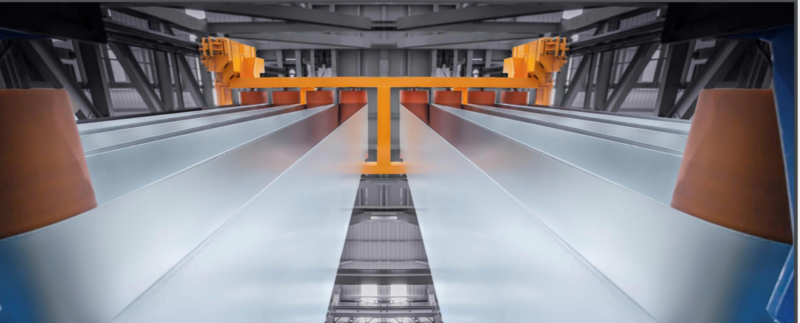

SIAS® (AUTOMATED SURFACE INSPECTION SYSTEM)

Fast, simple, reliable

- Infrared, edge-hole

- Reduced manpower

- Trustworthy report

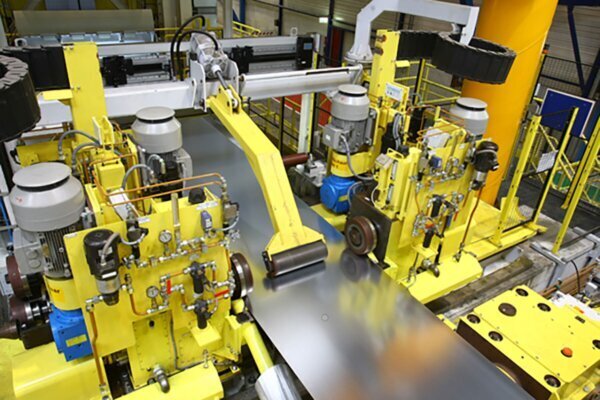

SKIN-PASS MILL

For a secured coil finish

- Up to 1500t

- 2-High, 4-High

- Short work roll change time

TENSION LEVELLER

For tight flatness tolerances

- 6-High design, up to 45t

- Compatible with HSS

- Wet and dry applications

DYNAWIPE (ZINC WIPING SYSTEM)

For perfect coat with zinc savings

- Fast coating transition

- Full mechatronic package

- Low maintenance

SCALE BREAKER

Strip tension up to 100 Tons

- Designed for HSS

- Improved flatness

- Maximized speed factor

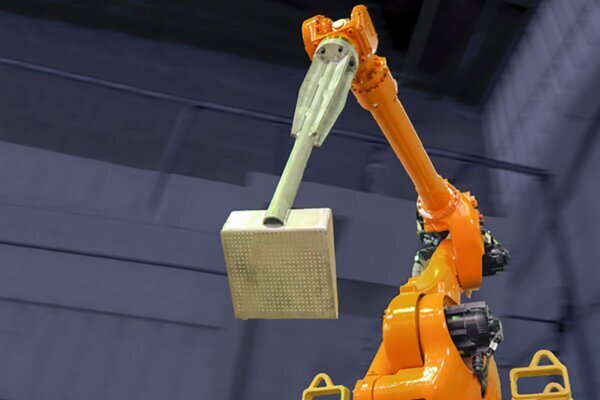

DROSS REMOVAL ROBOT

For a safe and qualitative zinc control

- Bath sampling option

- Improved operator safety

- Better bath quality

SIDE TRIMMER

Dynamic Width Adjustment

- Edge Monitoring system

- Increased line availability

- Reduction of yield loss

ROLL COATER

Optimum coating thickness

- User friendly operation

- Hydraulic DynaCoater®

- Faster ramp-up

PICKLING LINES

Economical operations

- Continuous or Push-Pull

- Up to 400 mpm

- Automatic acid control

CONTINUOUS ANNEALING LINES

High-end & fast processing

- High throughput rates

- Compatible with AHSS

- Automotive exposed quality

CONTINUOUS GALVANIZING LINES

Best protection to add value

- All coatings and steel grades

- Fully automated operations

- Automotive exposed quality

ORGANIC COATING LINES

Uniform paint for all applications

- Automatic line presetting

- Hydraulic DynaCoater®

- Integrated eco solutions

ELECTROLYTIC CLEANING LINES

Best surface before annealing

- Alkali and electrolytic cleaning

- High pressure rinsing

- Optimized utility consumption

RECOILING AND LEVELLING LINES

High performance for final touch

- Laser welding for coil build-up

- Levelling and side trimming

- Visual and automatic inspection

ELECTROLYTIC TINNING LINES

Protect your packaging

- MSA electrolyte

- HCD cell for chromium plating

- Multi-roll tension levelling

STAINLESS ANNEALING & PICKLING LINES

- Hot, cold or combi APL

- High turbulence Pickling

- Surface finish with Skin-Pass Mill